| UN SDGs | Our Goal | KPI Measurements | Progress in 2022 | Progress in 2023 | 2025 Target |

|

Goal 12: Responsible Consumption and Production

|

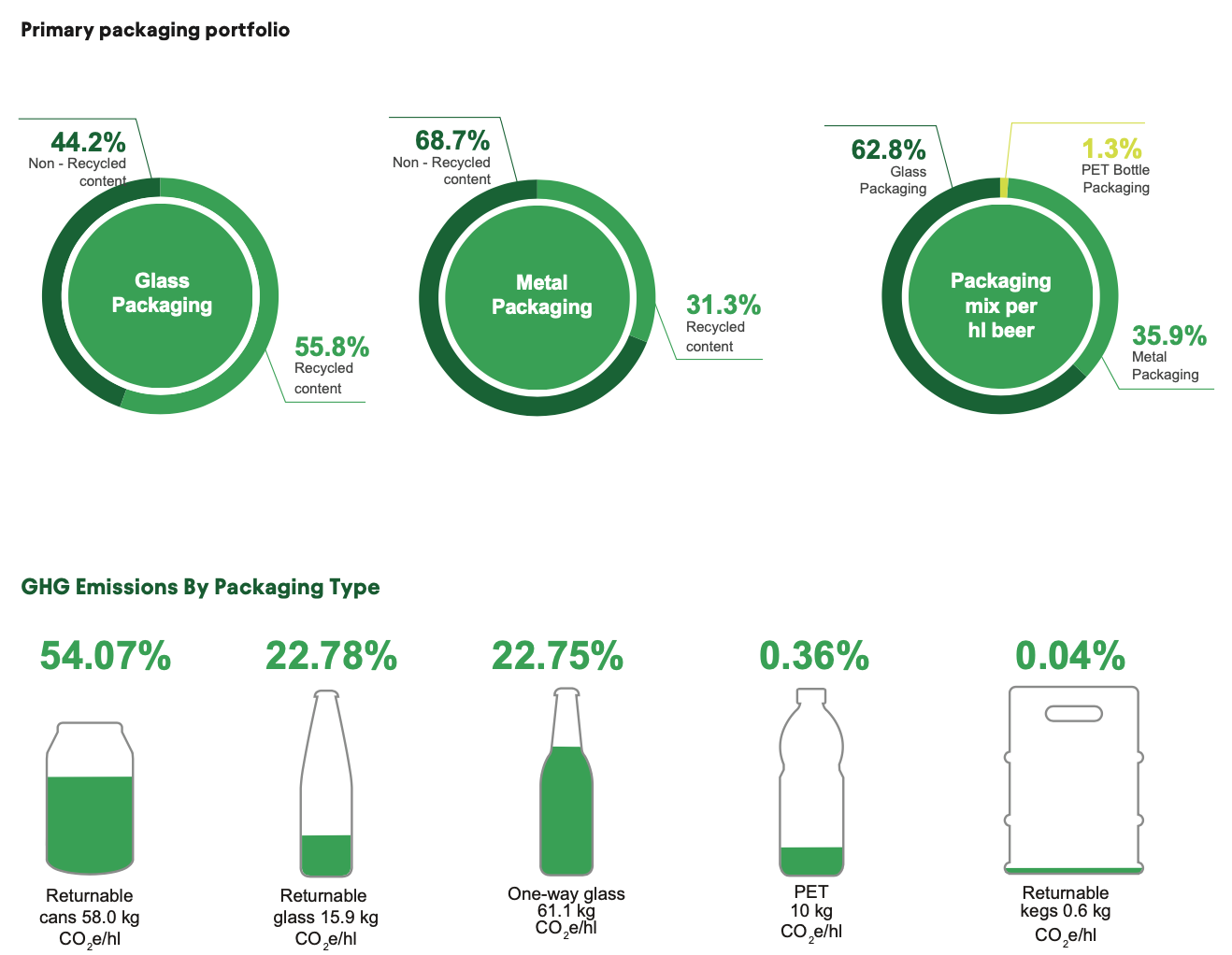

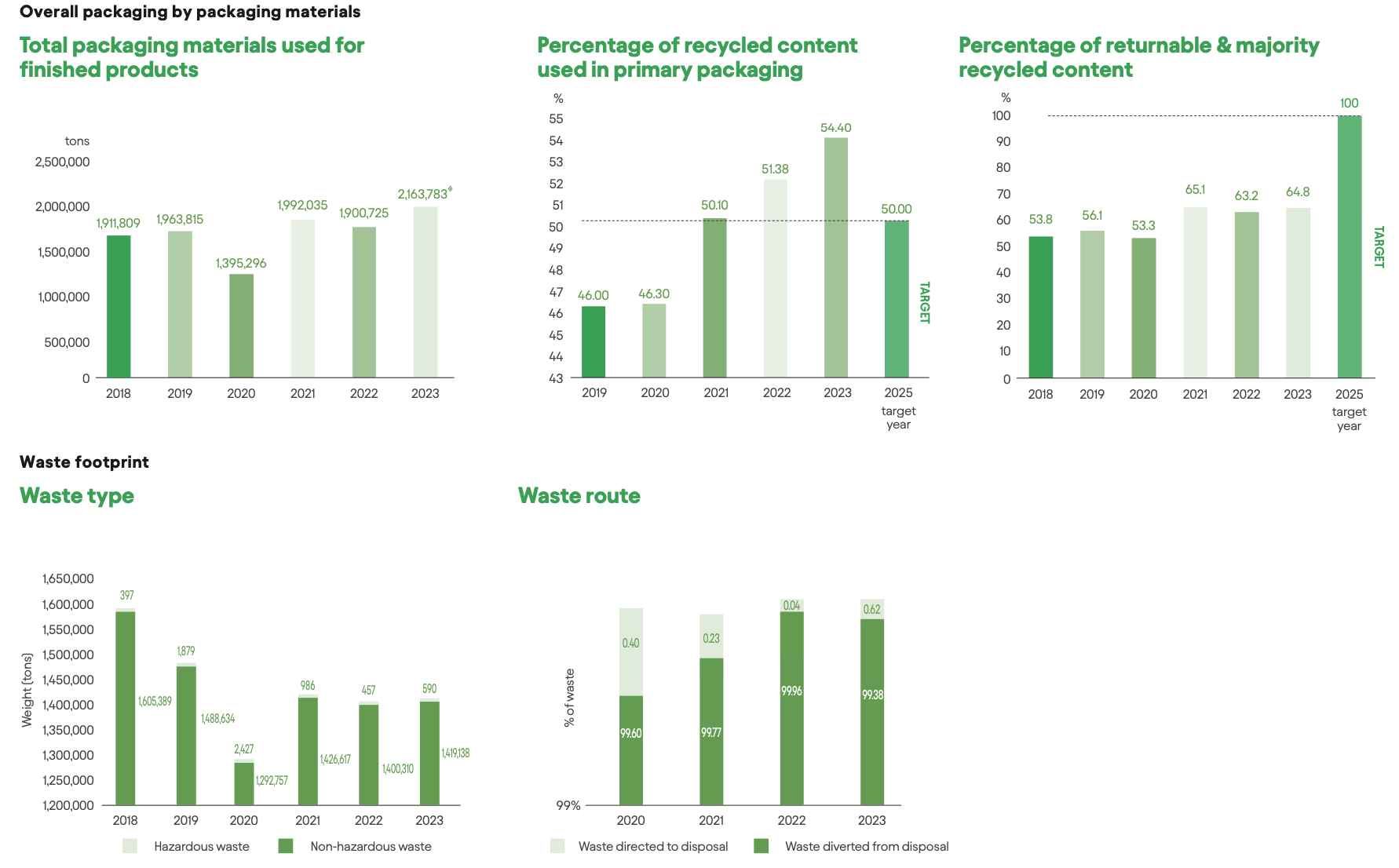

100% of our products are in packaging that is returnable or made from majority recycled content | % of products in returnable packaging + % of products in packaging made from majority >50% recycled content | 63.2% | 64.8% | 100% |

| To increase products in returnable packaging | % of products in returnable packaging | 50.2% | 49.4% | 100% | |

| To increase products in one-way packaging made from >50% recycled content | % of products in one-way packaging made from >50% recycled content | 13% | 15.4% | ||

| To increase % of primary packaging made of recycled content | % of primary packaging made of recycled content | 51.4% | 54.4% | >50% | |

| To increase recovery volume of our primary packaging materials | Weight in tons | 147,528 | 111,398 | 120,000 | |

| To increase recycling of by-products and waste | % recycling of by-products and waste | 99.96% | 99.87% | No target |

Our suppliers collected 7,877 tons of cullet for recycling in 2023.