| UN SDGs | Our Goal | KPI Measurements | 2017 Baseline | Progress in 2022 | Progress in 2023 | 2025 Target |

|

Goal 6: Clean Water and Sanitation

|

To improve water availability and quality in our communities in high-stress areas | % of our breweries in APAC have conducted local activities, identified water issues specific to their community and found appropriate solutions | 0% | 100% | 100% | 100% |

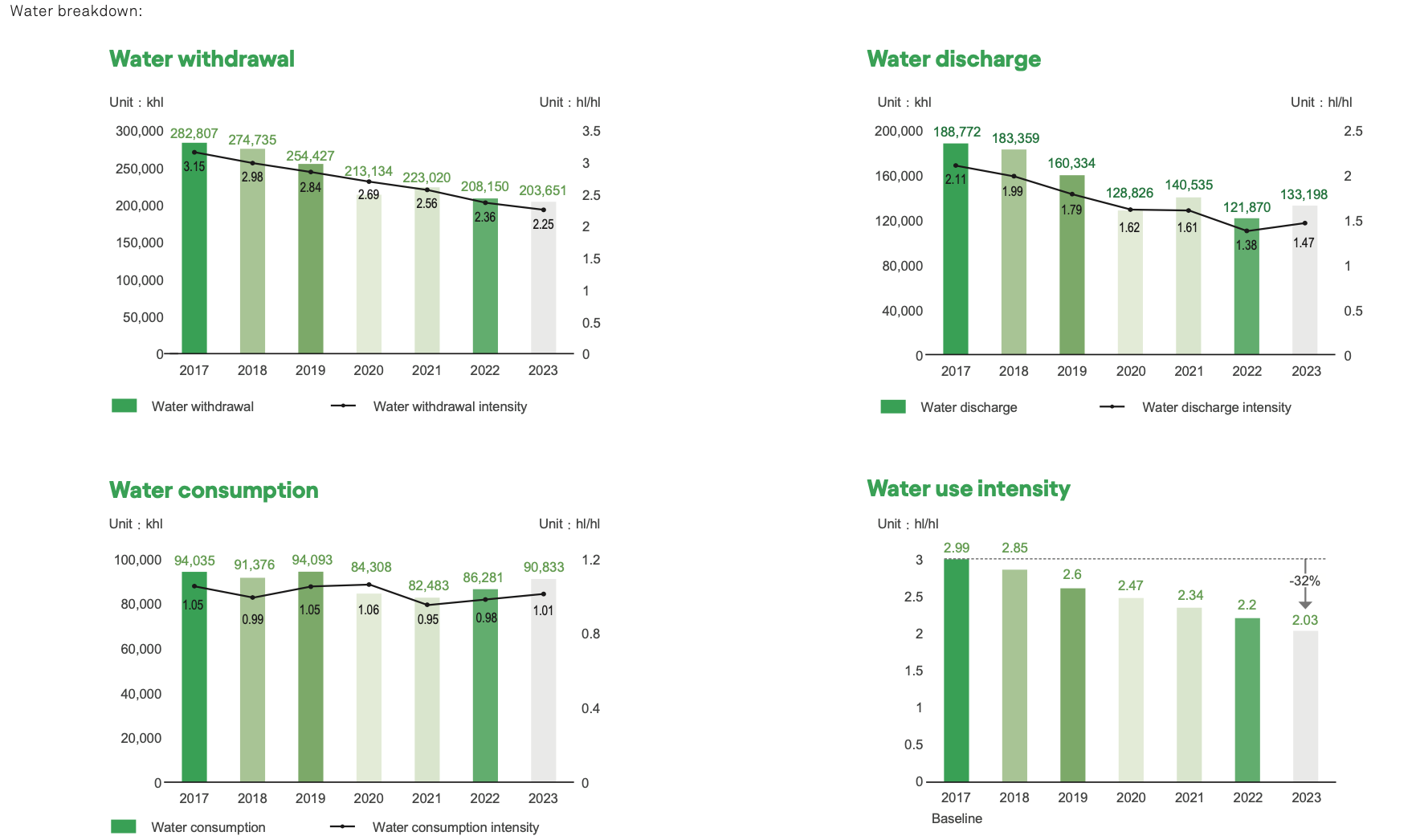

| To achieve water usage intensity of 2.0hl/hl in all areas including 100% of high-water stress areas | % reduction (hl/hl) of water usage intensity since 2017 | 0% | 26% | 32% | 33% | |

| Promote water reduction program among our suppliers, encouraging them to reduce water usage throughout their operations | % of operation facilities that applied water reduction program | 100% | 100% | 100% | 100% |

| Water aspects | Our process | Relevant water users | Our management |

| Water Withdrawals | To produce our beverages, our breweries source water from various providers, including third-party water utilities, groundwater, and surface water. However, water withdrawal for the purpose of exporting to third parties is not included in our reporting scope, as it is not utilized by our own operations within the breweries under consideration. |

• Local communities • Water utilities |

Water withdrawal is quantified and documented on a monthly basis for all sites, irrespective of the water source. This measurement and reporting process is aligned with crucial production levels and conducted on an eight-hour per shift basis, allowing for continuous benchmarking and necessary corrective actions. Additionally, water withdrawals are reported for each individual site based on the specific water sources utilized. |

| Water Consumption1/ Water Usage2 |

Agriculture (Supply Chain): Water is utilized in agricultural processes for the agricultural products we procure, however, it is not included in our water consumption or usage data as it falls outside the reporting scope for brewery operations. Conversion of Brewing Ingredients (Supply Chain): Our suppliers require water to convert raw materials and agricultural produce into ingredients for our products. For instance, the conversion of barley into malt necessitates water. Nevertheless, this particular process is not accounted for in our water consumption or usage data as it lies beyond the reporting scope for brewery operations. Brewing Operations (Our Operation): Water is consumed in our breweries for production and operational purposes. Sanitary Water Use (Our Operation): Within our breweries, we provide clean water for workers’ handwashing, toilet flushing and showering. End of Life (Our Operation): As part of the water treatment process, some wastewater is evaporated into the atmosphere before entering the biological treatment system. During this phase, water is lost and considered as part of our consumption. |

• Our farmers (supply chain) • Our production and operations |

We perform water risk assessments at all of our breweries including the ones in water-stressed regions. Our objective is to decrease overall water consumption by implementing enhancements in water usage efficiency. Annually, we expand the number of facilities that reuse reclaimed water. Furthermore, newly established beverage operations adhere to strict guidelines for increased levels of reclaimed water reuse. We ensure the provision of fully operational and secure WASH (Water, Sanitation and Hygiene) services to all workers.

|

| Water Discharges | The majority of effluent from our breweries is directed to registered third-party treatment facilities, while a smaller portion of treated effluent is discharged into surface water. | Local communities | We subject all wastewater from our breweries to treatment through an internal biological treatment plant before appropriately discharging it into surface waters or municipal wastewater treatment plants. The daily recording of wastewater discharge volume and location is managed in our VPO data management system. Our objective is to progressively decrease discharge quantities by implementing recycling and reuse practices for the treated wastewater. |

| Water Intake Quality |

Conversion of Brewing Ingredients and Brewing Operations Ensuring compliance with food safety standards and adherence to relevant limits is crucial, particularly when it comes to the water utilized in the production of our beverages. |

Our production and operations | We have established standardized procedures and protocols to measure and monitor the quality of water withdrawals. Water quality data is diligently recorded and tracked using our VPO data management system. Any discrepancies between the incoming water quality and internal specifications are promptly addressed for each water intake. Certain parameters, such as pH value, are regularly checked for every brewery. |

1Water consumption includes water contained in our final product and water loss from evaporation before treatment.

2Water usage includes water consumption (see the footnote above) and water being reused in operation.

Two breweries in India have achieved 100% Zero Liquid Discharge in their brewing operations.